Australian wine is world-renowned, and vineyards across the country go to great lengths to grow the perfect grape. Irrigation is paramount to achieve this in a hot climate, so farmers are always looking to deliver water to vines in the most efficient way possible. Consequently, when Yenda Prods Irrigation undertook a project for vineyards near Griffith in New South Wales (NSW), it selected a Sulzer axial split case pump to deliver efficiency improvements of 3% to 5% compared to competing designs.

Dry and earthy

Many new world wines are produced in hot, arid areas — so irrigation is a key aspect of wine production in these regions. Being able to control the water supply to the vine can contribute to a grape with the desired characteristics, which hopefully results in a good vintage.

Irrigation systems rely on pumps to move water to where it is needed throughout the vineyard — an operation that takes up a sizable chunk of the total power consumption. With these systems operating for extended periods, even marginally improving the efficiency of the system can provide sizeable long-term energy savings, maximizing the cost-effectiveness of wine production.

Laying the groundwork

Yenda Prods Irrigation is a major irrigation company within the NSW region. Famed for introducing new technology and practices to the water industry, it was approached by a customer to improve efficiency and reliability of the systems installed at its Cauduro & Poloni site. To accomplish this, energy and system audits would be required to find the optimal way to achieve the constant flow rate of approximately 256 liters per second needed by the vineyards.

The pumps, pump stations, pipes, filtration, mainlines and valves were all analyzed along with input from a leading irrigation consulting engineering firm based out of Adelaide, South Australia, to generate the required duty point.

Using this information, it was determined that combining two of the pumping stations, reducing the number of pumps from three to one and connecting the farms with new mainlines was the optimal approach. However, this relied on sourcing a highly efficient pump that could meet the duty requirement.

Serving the right solution

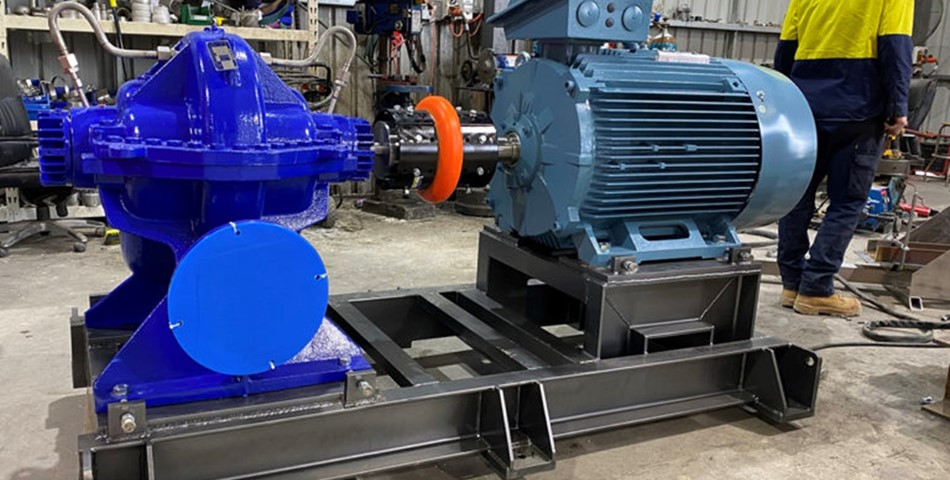

After assessing available options, Yenda Prods Irrigation selected a Sulzer axial split case pump. A global pump original equipment manufacturer (OEM), Sulzer offers exceptional experience in providing specialized pumps for irrigation applications. The pump selected could meet the duty point of 256 liters per second at a 57 m head with 87.1% overall efficiency. Furthermore, it offered low net positive suction head required (NPSHr) of 3.2 m — another key advantage.

The robust construction of the Sulzer pump was also preferred. Irrigation water often contains abrasive particles, which can cause premature wear to key components such as the impeller. To ensure that efficiency was matched by reliability, a duplex steel impeller was specified to ensure long-term durability. Combined with additional filtration systems installed by Yenda Prods Irrigation, this would reduce downtime so that the vineyards could properly capitalize on the energy savings.

“Sulzer, with its range of hydraulics, duplex impeller material, excellent efficiency and low NPSHr, was a very good fit for this application,” said Damon Cammish, fabrication manager and mechanical design engineer at Yenda Prods Irrigation.

The yields of a perfect pump

During the first year of operation, the pump has boosted process reliability while delivering the high efficiency expected. This has resulted in reduced operating costs, allowing the sites to deliver essential water to the vines in the most cost-effective way possible.

Ramandeep Singh Saroya