Used to regulate the flow of liquid, gasses, or any kind of fluidized solid, valves are an essential part of pipelines and multiple processes across many industries.

Industries such as chemical, power, metalworking, and oil & gas all have an increasing demand for innovative valves that meet the sectors’ requirements. To fulfill these demands, the valve production sector needs to substantially lower fabrication costs and the development time, while keeping up with the industry’s innovations.

Here are 7 valve design trends that should be taken into account by every valve manufacturer:

- Control Valves — One of the Main Valve Design Trends

With an expected Compound Annual Growth Rate (CAGR) of approximately 6.6% between 2014 and 2018, the manufacture of control valves is enhanced by the Oil and Gas industry in proportion to the refinery automation and control needs. Moreover, these valves have applications in deepwater exploration activities. Designing control valves includes all categories, for example, sliding stem control valves (mainly used in the oil and gas industry) and rotating shaft control valves (predominantly linked to power generation, water and wastewater, and chemical processing industries).

- Smart Valves are Gaining Popularity

For subsea oil and gas, intelligent control systems with an integrated embedded processor and networking capability for valve trees is becoming imperative. This is of the most powerful valve design trends. The increased reliability and responsiveness of these systems is preferred for industry standard electro-hydraulic control systems as they allow remote monitoring through a central control station.

A significant advantage of smart valves is that they prevent the consequences of damage or blockage in the pipeline network. This is enabled due to the capacity for reconfiguring piping and networking systems.

- Growth in Automatic Valves Demand

The process of choosing a type of valve for an application must take into account, among other criteria, the leakage rate, the safety requirements, the nature and components of what is flowing in the pipeline, the amount of acceptable flow and the scale of operation. Split into 2 broad categories – standard and automatic, valves have a wide enough market to include them all, especially due to the significant price difference as well as the versatility of standard valves.

As most of them are leak-free, standard valves meet emission and safety requirements. Also, the majority of them, especially the rotary shafts, are easy to convert to automatic actuation, which can be controlled by an automatic actuator.

Automatic valves, on the other hand, which include electric, hydraulic, pneumatic, solenoid, and digital mechanisms, are gaining popularity among manufacturing plants that require unmanned operations with a precise flow modulation. The main advantage offered by automatic valves is the advanced preventive maintenance ability, eliminating the risks of shutting down the operation as often as the standard valves do.

Rapid changes in technology and the capabilities of computer-generated control systems is causing automatic valves to gain momentum in the global market.

- Integrated Electronics

An important trend for servo and proportional valves is the integration of electronics into the valve. Presently, most integrated circuits feature digital electronics with powerful processors for decentralized intelligence on the component level.

Hydraulic valves, for instance, enjoy a significant share of the valve market, are constantly being improved with new mechanical designs. These innovations are incorporated into the digital electronics and onboard electronics and have a direct connection to field bus systems.

- High-Performance Globe Valves

Over the last few years, valve production companies across the world have developed high-performance globe valve design to overcome the problems of the conventional globe. This involves reduced flow capacity, noise, pressure drops, cavitation issues, and difficult manual operation to name a few.

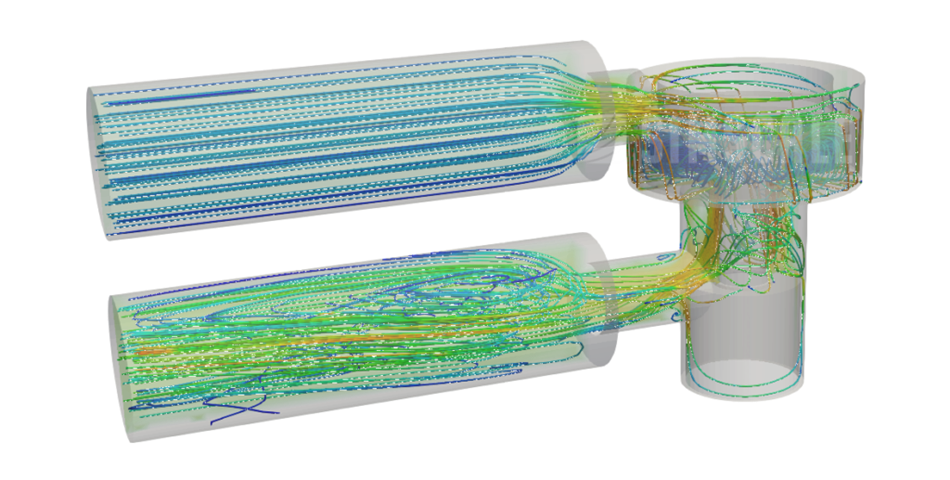

Using CFD and FEA simulation tools, valve manufacturers have a primary focus for optimizing the valves’ design. The resulting high-performance globe valves include new features like non-rotating stem globe design, in-suite seat arrangement, seal-welding of threaded seat ring, and guided disc arrangement, which enhances the high sealing performance and requires less hand wheel effort.

- Butterfly and ball valves

Quarter-turn valves are dominated by butterfly and ball valves. Ball valves are mainly found in pipelines, the oil and gas industry, gas storage applications, tank farms, offshore production platforms, and specialized LNG applications. The triple offset butterfly valve is preferred, due to its applicability in offshore platform installations.

- Increased Usage of Simulation Software

3D simulation software can now be used to analyze and test various solutions without the need to build and test multiple designs and prototypes.

Helping valve manufacturers develop high-quality products worldwide, SimScale includes all the functionalities you need for secure and reliable results. Ball, butterfly, globe, gate, check, hydraulic, dump, industrial plug, diaphragm, relief, pinch, poppet or any other type of valve can be easily simulated with the SimScale cloud-based platform.