Choosing valves for severe service applications can be particularly challenging. The process is always punishing, and these valves are invariably critical to plant operation, so selecting the right valves is paramount. “Severe service” usually involves very high-pressure drops and flashing, cavitation, or outgassing in liquid service. Corrosion and temperature extremes may also be encountered, as well as mixtures of vapors, liquids, and solids—which can plug passages and erode internal components. Selecting the right valves for these applications is not easy, but a step-by-step methodology can help.

Step 1: Evaluate the process

The severe service selection process starts with a solid understanding of the application. Most users have the normal process conditions well defined, with a firm grip on the inlet and exit pressures, process temperatures, and process media characteristics. However, they often fail to appreciate how those conditions can vary during abnormal situations.

Step 2: Understand the valve challenges

Once the range of process conditions have been defined, the user needs to evaluate how those conditions will impact the valve. Here is a partial list of potential valve challenges:

- High pressure drop – vapor applications create high velocities, high sound levels, and high vibration.

- High pressure drop – liquid applications tend to flash, cavitate, or outgas. Valve degradation may be unavoidable, but better designs can extend service life.

- Cryogenic temperatures embrittle metals and make sealing difficult, requiring special materials of construction.

- Very high temperatures, thermal expansion, and gradients require specialized alloys and carefully chosen components.

- Liquid/vapor two-phase flow create cavitation and choked flow.

- Entrained solids and particulates cause erosion and plugging.

- Three-phase combinations of liquids, gases, and solids are particularly destructive.

- Corrosion can occur in many forms, and each must be addressed differently.

Most severe service applications involve some combination of these challenges, and all must be addressed during valve selection.

Step 3: Consider solution options

With a solid understanding of the process conditions and valve impacts, the user is now ready to start valve selection. Unfortunately, there are a dizzying array of alternatives, but only a few will perform well in a specific application.

A starting point for valve selection is to look at the body design, which should be appropriate for the application. Angle valves are good for two-phase liquid cavitating/outgassing service because the liquid/vapor combination can clear the valve, minimizing damage to the seat and valve body. Angle valves are also common in turbine bypass applications.

In some cases, the piping configuration does not easily accommodate angle style valves, so straight through body styles must be used. Fortunately, there are anti-cavitation trim designs suited for these applications as well.

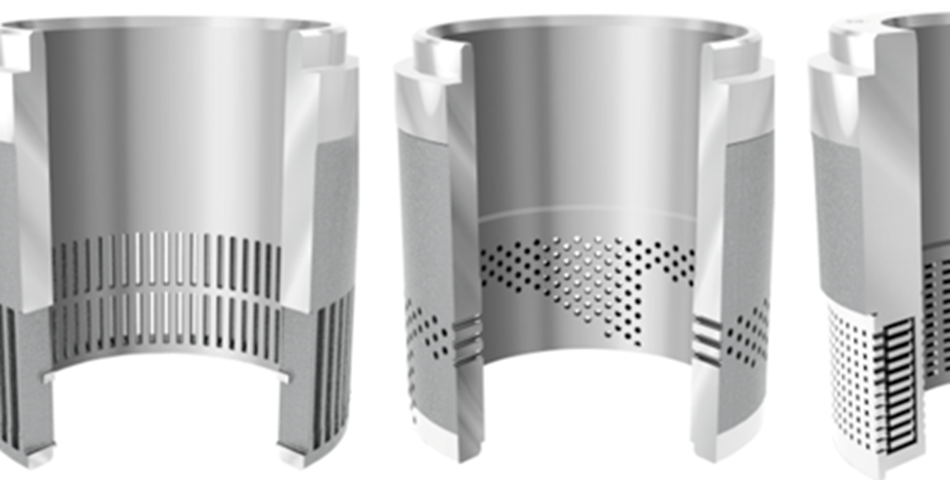

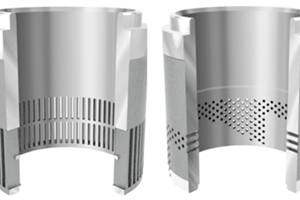

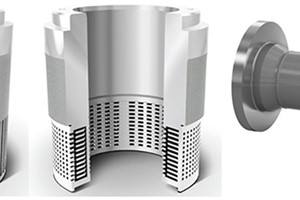

High pressure drop vapor application valves are designed to handle high velocity flows, while reducing noise and vibration. Low noise trims incorporate slots or holes to separate the flow into parallel paths, and then utilize numerous stages to manage pressure drops and reduce sound levels.

Anti-surge valves incorporate low noise trims with specialized high capacity, intelligent diagnostic digital positioners to achieve the required extremely fast response and high level of reliability.

Step 4: Use suitable materials

Careful material selection is critical for severe service applications. Trim and body components must resist damage from cavitation, flashing, and erosion, and packing materials must endure high temperatures and pressures. A severe service valve will incorporate a variety of materials for different components to best address the conditions each is expected to encounter.

Step 5: Seek advice

The number of valve component options can be overwhelming, so it is advisable that the user seek help and advice from whatever source is available.