We are the butterfly valve manufacturer which is also a provider of two types of eccentric butterfly valves, the double and triple eccentric butterfly valve. The double eccentric butterfly valve is mostly used in power generation and petrochemical applications, while the triple eccentric butterfly valve is used in more demanding industrial applications.

The butterfly valve comes from the family of the quarter-turn valve. It is named for its butterfly disk, which serves as a gate to open or shut the valve. The butterfly valve looks identical to the ball valve. The benefits of our butterfly valves include reliability, simple working, and fewer maintenance needs.

Definite Guide to Butterfly Valves

The butterfly valve is a flow control device that utilizes a rotary disk to control the flow medium in a system. Disk stays in the passage but because it’s very thin, offers very less resistance to the flow.

Butterfly valve technology has grown significantly over the last half-century, and also its industrial popularity. This popularity is due to its quarter-turn operation, the tight closure, and its availability in a variety of design materials and sizes.

Butterfly valves have many advantages over other types of valves, such as an economic design that is built of fewer parts which makes it easy to maintain and repair. The wafer-design body and comparatively lightweight minimize the expense and installation cost, equipment, piping support, labor, and time of installation.

What Are Butterfly Valves Used For?

Initially, butterfly valves are used for water applications only, but improvements in designs and materials have made it possible for them to be used in growing industrial fluid applications. Nowadays, butterfly valves can be used in almost any plant handling many fluids.

Some of the industrial applications for which Butterfly valves are used, are Supply of water, wastewater treatment, Lube System, Fire protection services, Food processing, pharmaceuticals, and many more.

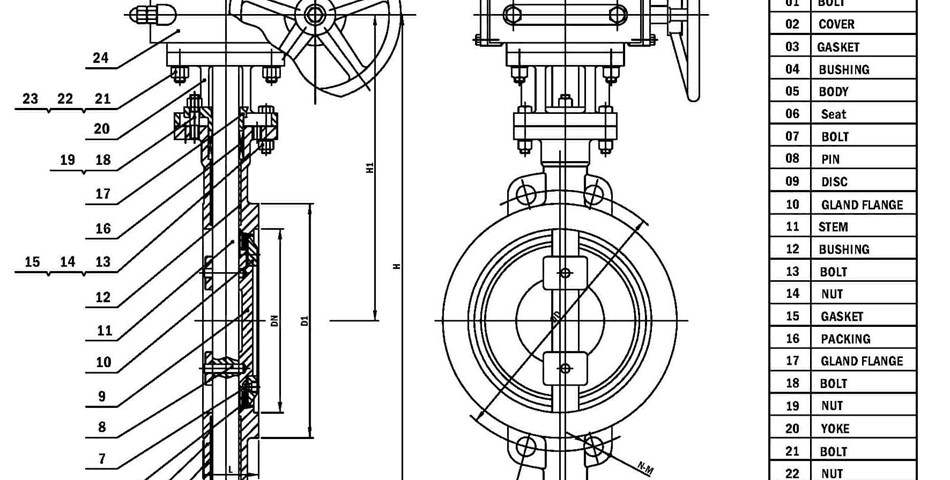

Butterfly Valve Parts

Body: The valve body houses the operating parts of the valve and is built to fit in between the flanges of the pipe systems. There are various body shapes whose variations are discussed further. Lug and wafer are the most common body styles.

Disc: The disk is the flow closure component of the butterfly valve. Many changes in disk design have emerged relative to disk and stem alignment to enhance flow, sealing, and operational torque.

The disk is like a plug, or a ball. Rotating the disk with a one-quarter or 90-degree turn opens and shuts the butterfly valve.

Stem: The stem attaches the disk to the actuator, also called the wheel or the handle. The stem transmits the rotation of the handle to the disk. The actuator cannot manually open or shut the disk without it.

The stem is shielded from the media in most resilient seated projects, allowing for effective material selection in terms of cost and mechanical properties.

In high-performance designs, the stems are in contact with the media and must thus be compliant and have the requisite strength for seating and disk removal from the bench.

Seat: A resilient butterfly valve employs an interference fit between the disk outer edge and the seat to ensure shutdown. The seat material may be made from a wide variety of various elastomers or polymers. The seat may be fixed to the body, or it may be pushed or locked.

In the case of high-performance butterfly valves, the sealing can be created by an interference-fit seat or a line-energized seat design, where the pressure within the pipe helps it to maximize the interference between the seat and the disk outer edge. The commonly used seat materials are polytetrafluoroethylene (PTFE) or reinforced PTFE (RTFE) due to a broader functionality and temperature range.

Metal seats are also provided in high-performance butterfly valves. These metal seats facilitate the use of a butterfly valve at a much higher temp. up to 1,000 degrees, F. Fire-safe variants are also provided that include the shut-off of the valve well before a fire, and the metal seal ensures sealing during and after a fire.

Actuator: The actuator is a mechanical device used to move or control a process or system. An actuator as part of an actuated butterfly valve is generally a mechanical system that takes energy, normally produced by air, electricity, or liquid, and transforms it into some kind of motion.

There are three main designs when it comes to actuator failure:

Fail Open is used to prevent overpressure when there is a loss in pressure.

Fail closed design is used in steam injection wells to prevent uncontrolled seam as it is extremely dangerous.

Fail in place is utilized where at the time of actuator failure, the processes cannot be shutdown.

How Does a Butterfly Valve Work?

A butterfly valve is one of the quarters turns valves that are used for shut-off or regulating services when placed in a pipeline. They house a ‘butterfly’ or a disc that looks like butterfly that is connected to a stem rod which rotated the disc to close the valve when it is turned to a position perpendicular to the flow.

Butterfly Valve Types by Actuation

There are two ways by which a Butterfly valve can be operated i.e., Manually (using a lever or a handle) or Automatically (using an actuator). These actuators can work using electrical power, hydraulic, or using pressurized air.

Electric Butterfly valve: An electric actuator is used to operate the valve here. An electrical actuator is a mechanical system used to transform electricity into kinetic energy in a single linear or rotational movement.

Hydraulic Butterfly valve: Hydraulic actuators are used when a large amount of force is required to operate a valve. The main design for the hydraulic actuator is a piston-type design.

Pneumatic Butterfly valve: Pneumatic actuators are generally used to monitor processes requiring a fast and precise action since they do not need a significant amount of motivating force.