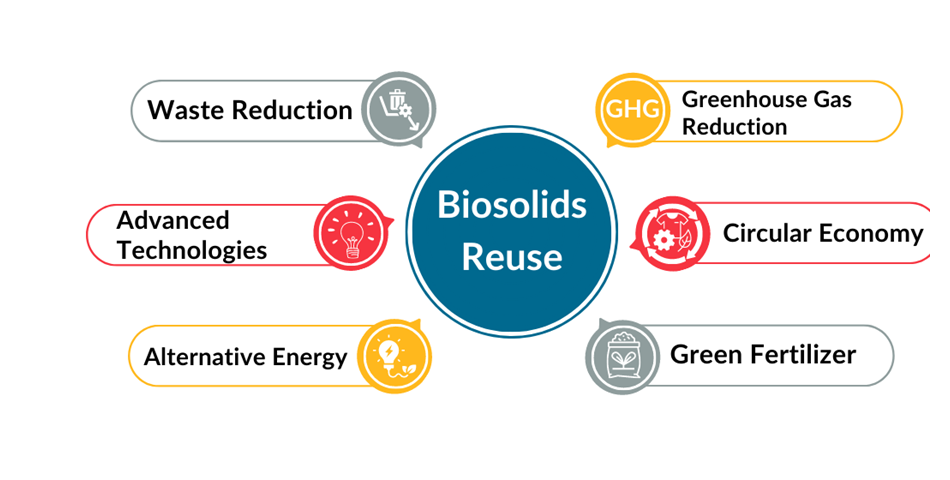

Biosolids Reuse: Why Now?

Biosolids reuse and land application is a decade-old strategy, yet we are seeing a current push to innovate as landfill space becomes limited and concern grows over greenhouse gas (GHG) emissions.

In Ontario, plans are underway to develop and implement a food and organic waste disposal ban regulation under the Environmental Protection Act. The anticipated regulation would support the beneficial reuse of organic resources, including biosolids and sludge.

Coming forth as both a necessity and an opportunity, reusing biosolids is one of the most sustainable ways to achieve a circular economy, ideally by eliminating waste and recovering renewable energy.

Reuse Options

New and evolving technologies have opened the door to many different resource recovery and reuse possibilities. Let’s review some of the options that are currently on the rise, starting with gasification.

Gasification

Gasification is a thermochemical process that converts biosolids at a high temperature (500 to 1,500°C) into ash and syngas. Syngas can be further converted into either energy, fuel or synthetic biofuels. The ash generated as a by-product can be used as a soil amendment.

Pyrolysis

The pyrolysis process involves thermochemical decomposition of biosolids at elevated temperatures (500- to 800°C). The pyrolysis process takes place in the absence of oxygen and results in process gas (pygas/pyrogas), oil and biochar. Pygas can be further converted to energy and biochar can be used for soil amendment.

Biogas and Renewable Natural Gas Production

Biogas is a renewable energy source that we can generate through anaerobic digestion of sewage sludge. It can be collected and used in boilers at facilities, converted to heat and electricity using combined heat and power engines, or cleaned and upgraded to renewable natural gas (RNG) for injection into the natural gas distribution grid.

RNG production significantly reduces GHG emissions and supports a circular economy as it converts the methane that would have emitted in the environment (from the decomposed residuals disposed in landfills) into renewable fuels that emits 21 times less potent GHGs from combustion.

Currently, the City of Toronto and the City of Hamilton have adopted RNG production. The Dufferin RNG facility in Toronto is expected to produce 3.3 million cubic metres of RNG each year. This will result in a fuel blend that is approximately 7 percent RNG. The City will use this low carbon fuel to power City vehicles and heat City-owned facilities, ultimately reducing their overall GHG emissions.

Compost

Dewatered raw sludge or digested biosolids can be composted, typically with other organic material such as wood chips or food waste, to produce a soil amendment product that can used for a variety of applications, including crop production, urban landscaping, domestic and community gardening, and municipal park application.

Composting can be accomplished both aerobically and anaerobically, although partial aerobic condition is the most common. Currently, different types of composting methods are in practice, such as aerated static piles, windrows, or in-vessel composting systems.

Land Reclamation

Another use for biosolids can be found in reclamation projects. Through the development of soils and soil cover, biosolids add improved nutrients and enhanced water-holding capacity. The application of biosolids increases organic matter and nutrient content, and helps to revegetate, reduce the bioavailability of toxic substances, regenerate the soil layer and improve slope stability.

Land Applications of Biosolids

Sewage biosolids have been used on agricultural land in Canada, the United States and Europe for more than 30 years. Biosolids contain nutrients and organic matters such as nitrogen, phosphorus, minerals and micronutrients. As such, biosolids can be spread or applied into agricultural soils as a soil amendment or fertilizer to enhance soil health, structure, moisture retention and permeability.

Biosolids enhance soil health by returning nutrients back to land and by sequestering carbon in soils, which helps reduce climate change impacts, as well as synthetic fertilizer and pesticide use. The Canadian Council of Ministers of the Environment encourages the land application of biosolids after they meet the regulatory standards. When they exceed the standards, biosolids can be applied to farm land as regulated.

PFAS and Land Application of Biosolids

PFAS, or Perfluoroalkyl and Polyfluoroalkyl Substances, are a group of human-made compounds that have been manufactured for over 50 years and when exceeding specific concentrations, pose various health risks. Being very persistent, they have found their way into our air, water, soil and waste streams, leaving trace amounts in our sludge and biosolids.

As a result, some public resistance and fear may arise about potential health risks associated with the land application of biosolids. However, wastewater treatment processes and biosolids facilities do not utilize PFAS chemicals, rather, wastewater and biosolids receive and convey trace amounts of PFAS that are used and encounter in our daily lives and products.

PFAS in biosolids do become a concern when collection systems receive sewage from industries that manufacture PFAS, or from firefighting and military operations. Risk assessments by different states in the United States have found that direct contact, inhalation, or ingestion of typical biosolids and other recycled residuals pose no significant health risk, including from the traces of PFAS they contain.

Biosolids to Fertilizer

There is a recent trend to produce fertilizers from biosolids. These fertilizer products provide equal or greater opportunity for agricultural use. These products are usually easy to store during the periods when the preferred end use is not available.

As an example, CHAR Technology uses their proprietary High Temperature (500-850 0C) Pyrolysis (HTP) technology in the absence of oxygen and can convert biosolids into three streams – renewable gas, heat and biocarbon/ biochar. The remaining solids can be converted into a fertilizer additive or soil amendment product known as biochar or sulfaCHAR. As per the technology provider, CHAR has demonstrated PFAS elimination from there biosolids samples using its HTP technology. PFAS compounds were eliminated from the solids at >99 percent after pyrolysis at 700 °C.

Moving Forward

There are many reuse options and technologies emerging, all with their own benefits and challenges. To be successful in adopting any of these strategies, it is important to consider the local market and end user’s availability, the laws and regulations in your jurisdiction, as well as any public or stakeholder feedback.

Biosolids reuse is on an upward trend and while research is still being completed, the benefits presented point to a much more sustainable, circular economy and environment.

Luxmy Begum