KSB Aktiengesellschaft, Germany, has supplied 21 pumps to Emschergenossenschaft for use in the Emscher sewer, also known as Emscher canal, which is currently Europe's largest waste water project.

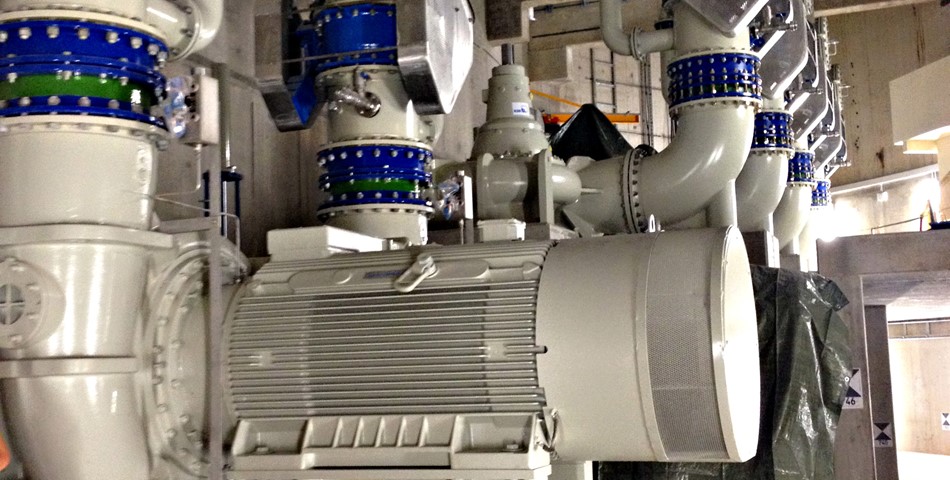

The pumps are employed as main pumps in two new pumping stations run by Emschergenossenschaft in Bottrop and Gelsenkirchen. Specially modified, the pumps from the Sewatec range were delivered for this project.

This pump type is used in numerous wastewater pumping stations all over the world. The biggest pump sets each have a drive rating of 470 kW and handle up to 6480 cubic meters per hour. A special technical feature of the pumps is their casing design.

Unlike Sewatec's standard casing, the casings for this variant were designed with tangential discharge nozzles by KSB engineers to achieve even better efficiencies. The impellers were also optimized to ensure excellent efficiencies without compromising on the high level of operating reliability.

The efficiencies the pumps achieved on the test facility exceeded the values established via the CFD (computational fluid dynamics) simulation. KSB's factory in Halle/Saale produced all of the pump sets for this major project, including two huge pumps in close-coupled design (photo) specially manufactured for the Gelsenkirchen pumping station.

The pumping stations in Bottrop and Gelsenkirchen are used to lift the waste water from the eastern Emscher valley to sewer sections located at a higher level.