What is coagulation and flocculation in water treatment?

Coagulation and flocculation are essential components of both drinking water and wastewater treatment. They provide a reliable process for treating water turbidity (the cloudiness or haziness of a fluid typically invisible to the naked eye), which is a key test of water quality. In wastewater treatment, they enable up to 90% reduction in suspended solids and organic loads.

All waters contain suspended particles. The smallest particles (colloids) are stabilized by the action of physical forces (static electricity) on the particles themselves and, because they all have a negative charge when suspended in water, they repel each other. This causes them to remain suspended rather than clumping together and settling out of the water. They might take days or even up to centuries to settle out!

Coagulation and flocculation are two separate processes, used in succession, to overcome the forces stabilizing the suspended particles. While coagulation neutralizes the charges on the particles, flocculation enables them to bind together, making them bigger, so that they can be more easily separated from the liquid.

The coagulation process in water treatment

This destroys the process whereby tiny particles repel each other and promotes their consolidation to bigger ones that are able to stick together. The bigger the particle, the easier it is to separate from the liquid. The use of coagulants for treating water goes all the way back to around 2000 BC when the Egyptians used almonds, smeared around vessels, to treat river water.

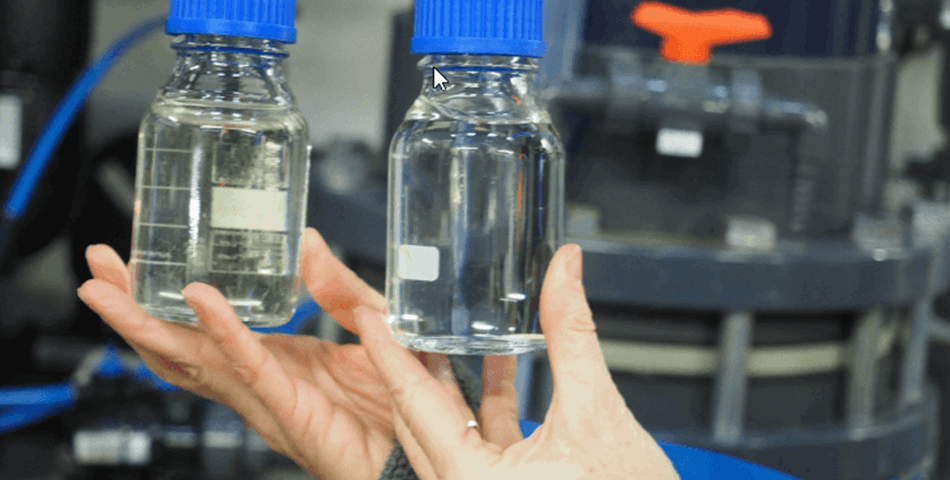

These larger ‘clumps’ of particles are called micro-flocs and still cannot always be seen by the naked eye. The water surrounding these newly formed particles should be clear – and this will signal that the particles’ charges have been neutralized. If it isn’t, more coagulant may be needed. Too much coagulant and the particles will revert to repelling each other – but predominantly by the reverse charge

Rapid mixing ensures the coagulant is properly dispersed to promote particle collisions. The metal coagulant hydrolysis products formed within 0.01 to 1.0 seconds tend to be the most effective for destabilization – this is why adjustment of pH and post-dosing of more coagulant is rarely effective after the initial coagulant addition.

One common type of rapid mixer is called a back-mix reactor, which normally consists of square tanks with vertical impellers. In many instances, they produce poor results, and WCS tends to design in-line mixers with velocity gradient control to provide the best conditions for rapid mixing.

Types of coagulants

Today, there are two types of coagulants that are most commonly used in water and wastewater treatment. Organic and inorganic.

Inorganic coagulants include:

- Aluminium coagulants - e.g. aluminium sulphate, aluminium chloride and sodium aluminate

- Iron coagulants - e.g. ferric sulphate, ferrous sulphate, ferric chloride and ferric chloride sulphate

Organic coagulants include:

- Polyamines

- Polydiallyldimethylammonium chloride (Poly DADMACs)

- Polytannate

The most commonly used inorganic chemical coagulants in water treatment

Aluminium sulfate is the most commonly used chemical for coagulation in wastewater treatment. Additional commonly used coagulants include sodium aluminate, ferric sulfate, and ferric chloride.

Which coagulant should you choose for water treatment?

In water treatment, metal coagulants such as the ones listed above are commonly used. Availability and affordability are the key considerations that generally influence the coagulant used. Aluminium sulfate is commonly available and affordable as well as being very effective.

However, other types of coagulants are also available:

- Synthetic coagulants may have high charge densities on relatively large molecules. Depending on how they are made, some of the synthetic derivatives may behave as a flocculant.

- Biopolymer coagulants from natural sources (such as fungi and plant sources). Generally, these produce less sludge, are less toxic, and are considered to be safer.

James Greenwood

www.wcs-group.co.uk/