KIST researchers have created solar and hydrothermal energy-based membrane distillation techniques. By using these specialized membrane distillation technologies for geographical climate applications, system efficiency is expected to be maximized.

Human survival depends on access to clean water. The amount of freshwater that can be utilized for drinking, however, is less than 3%. Around 1 billion people globally lack access to clean drinking water, and the number is projected to increase to 1.4 billion by 2050, according to research released by the World Meteorological Organization.

Water scarcity could be resolved using saltwater desalination technology, which creates fresh water from salt water. Researchers at the Korea Institute of Science and Technology have created a hybrid membrane distillation module that uses hydrothermal heat pumps and solar energy to reduce the amount of thermal energy needed during the desalination process.

The research team is led by Dr. Kyung Guen Song from the Center for Water Cycle Research.

Seawater desalination processes like reverse osmosis and evaporation are relatively common, but they are only effective at high pressures and temperatures. By using the vapor pressure created by the temperature differential between the flowing raw water and treated water separated by a membrane, the membrane distillation process creates fresh water in contrast.

Given that fresh water can be produced at pressures between 0.2 and 0.8 bar, or 50 and 60 ℃, this method has the benefit of requiring less energy. Large-scale operation, however, demands more thermal energy. Therefore, it is necessary to conduct research studies to decrease the usage of thermal energy in business operations.

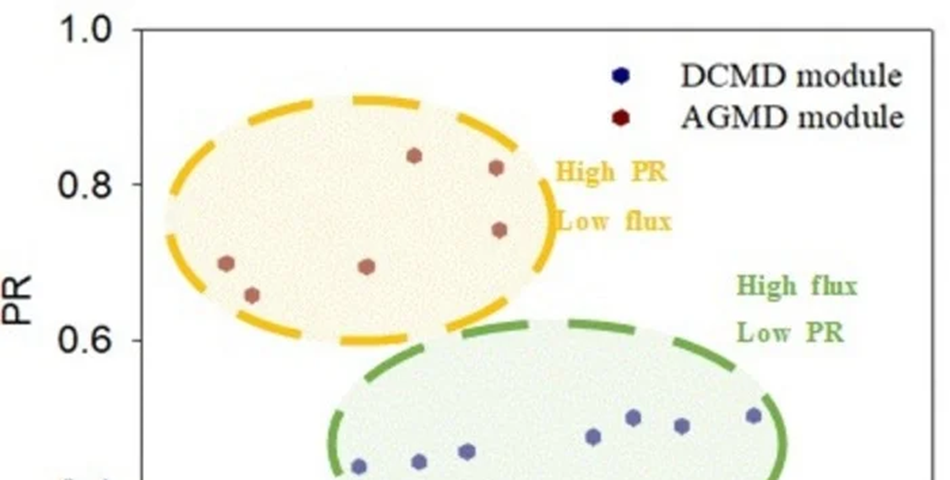

Mass and heat (energy) are transferred simultaneously during membrane distillation. Based on the mechanisms used to create vapor pressure differences on the treated water side of the membrane, which serve as the driving power, it is split into two types: direct contact membrane distillation (DCMD) and air gap membrane distillation (AGMD).

The method of producing water by direct contact of processed water with low temperature and raw water with high temperature to the membrane surface (i.e., DCMD) is advantageous for high energy supply.

Instead of direct contact between raw water and processed water, under limited energy supply situations, the efficiency is higher if the heat conveyed (heat loss) is decreased by air gaps. The mode that produces water by condensing over a cold surface and maintains air gaps between the membrane and the condensation surface (i.e., AGMD) is, therefore, preferred.

By conducting on-site experiments for a month to analyze the system efficiency and economy using solar energy and hydrothermal heat pumps, the KIST Research team created a hybrid desalination technology.

Compared to the membrane distillation process using only hydrothermal heat pumps, production increased by 9.6% and energy consumption decreased by 30% when the system worked in tandem with solar energy.

Additionally, a study of thermal energy consumption based on solar energy presence revealed that using solar energy as an additional heat source might boost membrane distillation plant process efficiency by up to 17.5%.

Dr. Song added, “Membrane distillation is not significantly affected by raw water quality, so it will be possible to supply drinking water to areas where raw water quality became heavily contaminated due to water pollution and areas where heavy metal detection is high.”

This study was funded by the Ministry of Science and ICT and carried out as a BRIDGE Fusion Research Development Program, which is a part of the STEAM Research Project.