Whether it be from a process or from Reverse Osmosis (RO)-based recycling or desalination, the challenge of waste brine disposal usually requires costly thermal treatment, leading to Zero Liquid Discharge (ZLD) – but a major technological breakthrough looks set to change all this. A new, non-thermal system that simply uses electrical energy and consumes only a fraction of the energy compared to thermal systems is now available.

Following its first full-scale demonstration plant, built and operated in India, this pioneering work (developed from Modern Water’s extensive knowledge of forward osmosis and osmotically-driven membrane processes), feels and operates just like standard RO systems - and doesn’t require specific expertise to operate it. Typically, expensive Seawater Reverse Osmosis systems have been deployed to concentrate brines to about 7-9 percent NaCl equivalent, but these are limited by the hydraulic pressure that membranes can withstand. More recently, some Plate & Frame and Disc-type RO configurations have been developed.

These can withstand much higher pressures than traditional spiral-wound Seawater RO membranes, but major challenges still remain in overall system design and sourcing of system components at such high operating pressures, which limits their applications. Peter Nicoll, Technical Director at Modern Water commented: “There is no such generalization of the word ‘brine’ in the wastewater industry and it covers the entire spectrum of salinity from cooling tower blow-downs to saturated solutions from production processes in the chemical industries.

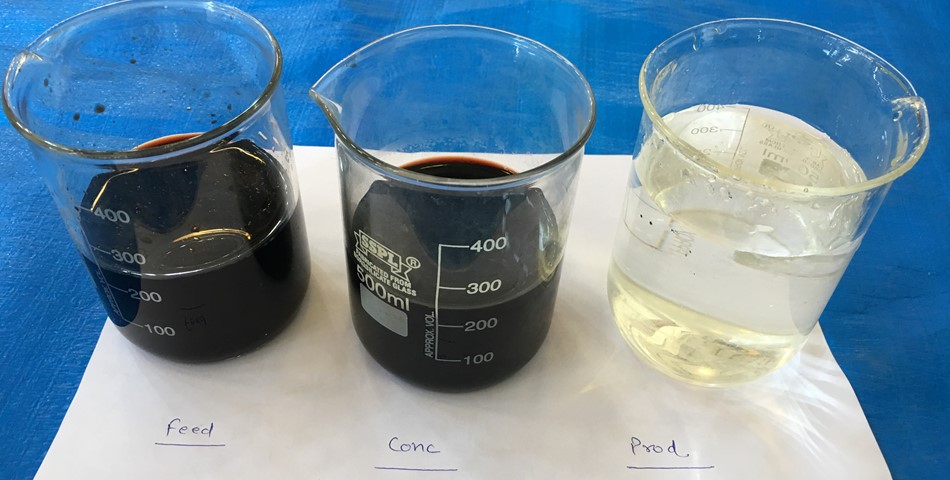

In the Indian market, what is common though to both water and wastewaters is that the effluent disposal standards do not permit any waters higher than 2100 mg/l of Total Dissolved Solids (TDS) to be discharged into surface waters or the land. Disposal of brine is a serious environmental issue, attracting more and more focus from the authorities – and the courts”. Nicoll also explained that with proper pre-treatment (and intermediate treatments for removal of sparingly soluble salts, heavy metals and organics), traditional seawater RO membranes are often used to concentrate wastewater brines to about 50-70,000 mg/l (5-7 percent) NaCl equivalent concentration, though theoretical possibility is somewhat higher at 9 percent.

To adhere to discharge laws, industries rely on thermal treatments like Multiple Effect Thermo-Compressor Evaporators or Mechanical Vapor Compressor (MVC) Evaporators. These distil out the water from the concentrated brine, thereby yielding wet salt, which is then disposed to a secured landfill. Since Thermal Brine Concentrators are costly and also difficult to operate continuously and reliably, significant effort has gone in to finding more efficient solutions. From solar pans to salinity gradient solar ponds, solar stills to psychometric evaporators, or Membrane Distillation to Capacitive Deionization, major investment has been expended to concentrate brine from the RO step, but with limited success that has not proved to be techno-economically viable and dependable for commercial usage.