Sources of industrial noise

Loud sounds in an industrial environment can emanate from a variety of sources, including reciprocating compressors, construction sounds, various machinery and vents. Other common source of noise are control valves, which generate noise in three ways: mechanical vibration of internal components, aerodynamic noise from turbulent gas flow, and hydrodynamic noise from cavitation. Point sources of noise, such as vents, lose energy quickly, while sound energy falls off with the square of the distance.

Control-valve noise is different since the sound radiates from the pipe itself. This creates a linear source of sound that loses energy more slowly than from a point source. Sounds from a valve fall off linearly with distance, so a doubling of the radius only cuts the sound in half.

Another poorly understood phenomenon of industrial noise is its inconsistent additive nature. If two 90 dBA noise sources are near each other, the resulting sound level is 93 dBA (+3 dB is essentially twice the sound energy). However, if a 90 dBA source is near a 70 dBA source, the net sound result is still about 90 dBA, because the louder sound masks the quieter one.

Cutting control valve noise

As mentioned previously, control valves create sound through mechanical vibration of internal components and aerodynamic noise from turbulent gas flow. As gas or steam flows through a control valve, the velocity increases in the narrow passages, creating sound waves that radiate from the valve and piping. Aerodynamic noise varies as the eighth power of the gas velocity, so high flow and high-pressure-drop applications can be exceptionally loud. Obviously, this is a problem for operators in the area, but the associated mechanical vibrations also tend to damage the valve.

Years of application data suggest that damage tends to occur in valves subjected to noise levels greater than 110–115 dBA, so vendors try to avoid control-valve applications with sound levels above that value.

Sound level can generally be abated using either source control (reducing sound at the source) or path control (keeping sound from radiating to the environment). Each method has its advantages and costs.

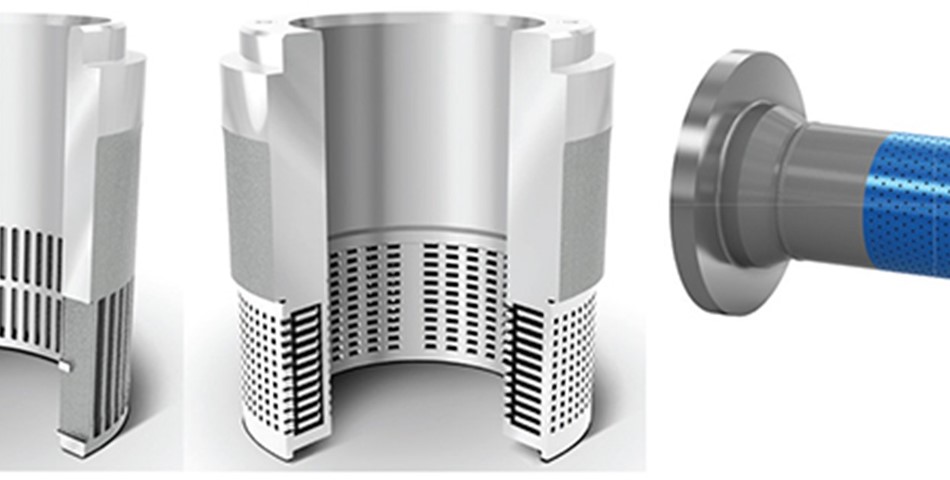

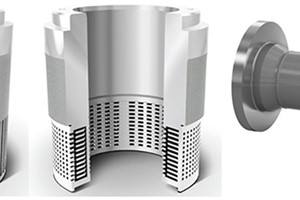

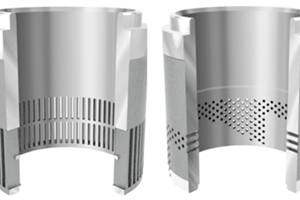

For control valves, source control is usually accomplished through pressure-drop staging or flow division (Figure 4). Pressure-drop staging reduces the overall sound by dividing a single pressure drop into a number of smaller steps. Smaller pressure drops reduce gas velocity and thus create less noise.

Flow division breaks up a single flow path into multiple ones, reducing flow-stream turbulence and shifting the frequency of the noise spectrum, and subsequently the sound created. These trims are effective at reducing sound, but the complex nature of the internals makes these valves significantly more expensive. They also tend to reduce valve capacity, making it necessary to buy a larger valve.

Path control is another means of sound reduction, and it muffles the sound to keep it from radiating to the environment. Path-control techniques can be as simple as using thick-walled pipe, adding pipe insulation, or encasing the pipe with acoustic blankets or sound-absorbing materials. Alternately, specially designed silencers or modal attenuators (Figure 5) use resonant chambers to cancel the noise through destructive interference.

Any or all of these techniques can be used to suppress the noise and limit operator exposure. It is worth noting that path control does not reduce the sound level, it merely keeps it from reaching the surrounding environment. If the noise level is over 110 dBA, damage to the valve could still occur.