There are many sophisticated ‘high-tech’ instruments available for flow measurement, but not all applications require the technology of those more complex instruments. In fact, in some applications simple flowmeters offer many advantages over the more technical instruments. The basic principle of flow measurement is: Flow rate is a result of the velocity of a fluid and volume. Although flowmeters may seem to be a modern invention, basic types were evident as far back as the early Roman era. They were often used for measuring water flow to households. The mathematical foundations of flow theory were evolved during the 17th century. There are many types of flowmeters now available to us. A few are: variable area, positive displacement, ultrasonic, and mass flowmeters. Each type has its particular set of features, and there is no universal or perfect flowmeter which is appropriate for all industries and applications. The correct flowmeter for any application is the one that will perform effectively in that application. Variable area type flowmeters offer many advantages over some more complex, technologically advanced types, making it the meter of choice for many flow measurement applications.

Tapered Tube

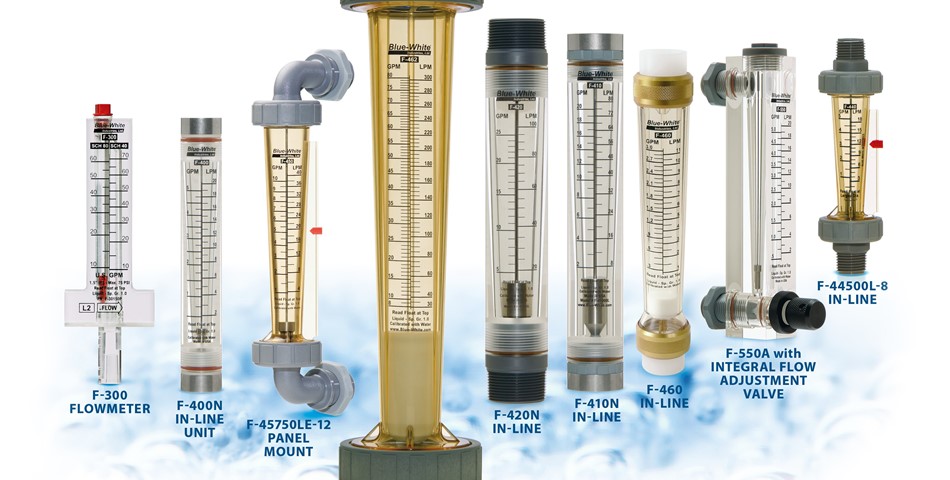

The variable area flowmeter is comprised of a vertically tapered tube through which the fluid to be measured is passed, from the smaller end of the taper and up to the larger end. As the fluid flows through the tube, it forces an indicator (float) upward. The clearance space between the float and tube increases as the float moves towards the top of the meter. As the area increases it requires a greater amount of fluid to force the float higher. So, by varying the taper of the tube as well as, the mass of the float and the length of the tube, different flow ranges can be calibrated. The correct installation of the variable area flowmeter, as with all flow instruments, is critical to performance. It must be plumbed into a piping system properly: that is, with the narrow part of the taper at the bottom. Typically printed onto or next to the tube is a calibration scale with the flow increments / measurements. The flow rate can be read by matching the increments printed on the tube with the edge of the float. A few industries where use of variable area flowmeters is common include:

The makers of ultrafiltration equipment (reverse osmosis systems) use flowmeters to measure output through the membrane, and to measure reject. Flowmeters play a critical role in helping to monitor the efficiency of the system. Ultra-pure water is used extensively in the manufacture of printed circuitry (cleansing of computer chips, particularly). Flowmeters are used both in the manufacturing and management of deionized water.

Solar-panel manufacturers recommend certain flow rates for optimum performance. Variable area flowmeters allow the installer and user to monitor flow economically, thus enabling critical process adjustments to be made. Because they measure actual flow, flowmeters offer an advantage over pressure gauges in filtration systems; as the filter becomes saturated (full), the flow rate drops. Just a glance at the flowmeter tells the operator if the filter needs cleaning, replacement of cartridges, or if there may be another problem, such as a tear in the filter material or a broken pipe. In the commercial swimming pool industry flowmeters are used to measure flow through the pool’s filtration system so operators and health inspectors, can easily verify an adequate amount of water is passing through that filtration system to ensure clean swim water.

Compatibility

It is highly recommended that chemical compatibility is checked and tested. It is best not to rely solely on compatibility charts. Many flowmeter manufacturers are willing to provide material sample kits, so purchaser can perform their compatibility tests. Specific gravity (‘weight’) of the liquid through the flowmeters affects flowmeter reliability and accuracy. Viscosity, the degree to which a fluid resists flow under applied force, also affects accuracy, as do elevated temperatures. These things must be taken into consideration when determining fluid flow.

Accuracy and Repeatability

It is important that the flowmeter chosen for your application provide both excellent accuracy and repeatability. Repeatability is the flowmeters’ ability to reproduce flow rates consistently under the same conditions. Repeatability is very important in the processing industry where tracking flow changes is so essential.

In summary, it is best to consider your flow measurement requirements, and if you’re uncertain what the best flowmeter for your application is, consult an expert who can provide friendly assistance and accurate information. Blue-White has a full staff of in-house engineers to provide the assistance you may require.

BLUE-WHITE® INDUSTRIES

www.blue-white.com