A water pump is a device used to increase water pressure to transfer it from one position to another. Modern water pumps are used worldwide to supply water for agricultural, municipal, industrial, and residential applications. Water pumps are also utilized to transfer wastewater in sewage processing plants. Recent water pumps most often are operated by electricity, but other energy sources are also used—for instance, gasoline or diesel engines. In some remote regions, such as desert areas, solar panels may be employed to supply electricity to small pumps.

Many types of pumps are employed in distribution systems. Pumps that lift surface water and transfer it to a nearby processing plant are called low-lift pumps. These pumps move large volumes of water at relatively low discharge pressures. Pumps that discharge water into arterial channels are called high-lift pumps. They work under higher pressures. Pumps that raise the pressure in the distribution system or lift water into a high storage tank are named booster pumps. Well pumps elevate water from underground and send it directly into a distribution system.

The three best positive displacement pumps for wastewater treatment

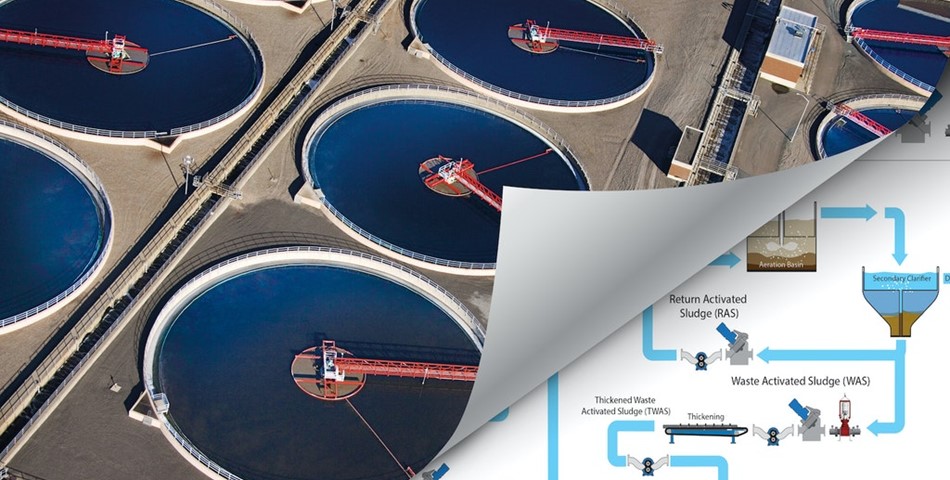

NETZSCH pumping systems enable efficient pumping in wastewater treatment plants

Wastewater places very high demands on the pumping system in some applications. We provide you with an overview of the various positive displacement pumps and their respective advantages.

Pumping systems face various challenges, from communal water treatment to industrial wastewater treatment plants. On the one hand, they are often faced with challenging conditions. This is mainly because the wastewater is often contaminated with wet wipes or other solids, resulting in a high risk of clogging and system failures. In addition, wastewater has a very abrasive and wearing effect. On the other hand, economic factors are increasingly coming into focus. Rising energy prices are putting more and more pressure on operators in terms of system optimization and cost reduction. The choice of the appropriate pump technology is of decisive importance here. Positive displacement pumps.

Rotary lobe pumps for pumping wastewater with a high solids content

The rotary lobe technology uses two lobes that move against each other, creating a vacuum on the suction side and sucking in the medium. The medium is pushed through the delivery chambers to the discharge side. Since the delivery chambers are self-contained, the rotary lobe pump can easily handle high solids content. Compared to centrifugal pumps, there are no large centrifugal forces or shear forces acting on the fluid when pumping liquids with rotary lobe pumps. Therefore, even abrasive media can have relatively little effect on the pumps' housing and rotary lobes.

Progressing cavity pumps ensure long service lives in wastewater pumping

In progressing cavity technology, a helical rotor turns against a stator. This creates delivery chambers between the rotor and stator, which move the medium from the inlet to the discharge side.

Due to their design, the delivery chambers of a progressing cavity pump are smaller than those of a rotary lobe pump. This means that rotary lobe technology is more recommended for large solids. However, due to the stator-rotor principle, progressing cavity pumps offer almost no possibility of clogging.

Simple principle, highly effective: Hose pumps for sewage pumping

Peristaltic pumps are a simple but effective type of positive displacement pump. A hose, which is placed in a pump housing, is squeezed with the help of rollers. The rotation of the rollers causes the pinch point to move along the hose, thus propelling the pumped medium.

Like the positive displacement pumps already mentioned, peristaltic pumps are particularly suitable for wastewater pumping because of their tolerance of high solids or fibre content of up to 70 percent. The exceptionally high suction capacity distinguishes these pump systems primarily for the transport of sewage sludge. The low shear rate additionally prevents foaming of the medium.

Grinding systems for pump protection in wastewater conveyance

The continuously increasing proportion of wet wipes in wastewater treatment can be counteracted with the help of various grinding systems and the appropriate pumping system.

Grinders can be divided into cutting plate macerators and twin-shaft grinders. With grinding using a cutting plate - as with the M-Ovas® from NETZSCH - solids are sucked up to the cutting plate by the flow. Larger parts accumulate in front of the cutting plate and are ground by the cutter head until they fit through the openings. This additionally protects downstream pump systems from clogging. The cutting plate is flexibly exchangeable, allowing you to determine the degree of grinding yourself.

Traditionally, centrifugal pumps are used to pump wastewater. However, this technology has an increased risk of clogging, so it quickly reaches its limits. Therefore, it is worth looking at the above-mentioned positive displacement pump systems, which offer numerous advantages - especially when dealing with media containing solids.