RMI Pressure Systems is making notable strides in the US mining sector, particularly with its advanced reciprocal pump solutions. The company is gaining recognition for supplying high-performance pump systems designed for both underground longwall mining and industrial press applications within the aluminium sector.

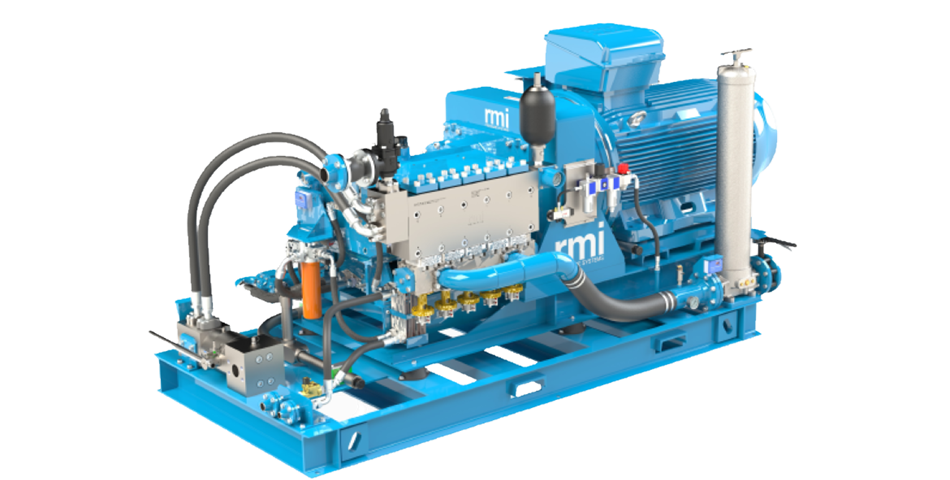

Gary Punton, RMI’s General Manager in the US, elaborated on recent contracts highlighting the company's innovations. Notably, RMI is providing its hydraulic power solutions for self-advancing roof supports at Warrior Met Coal’s Blue Creek longwall mine near Brookwood, Alabama. The solution is based on the company's popular five-plunger Quinmax S500 high-pressure reciprocating pump. Punton noted, “The manufacture, assembly and testing of two pump systems is planned for completion by end of the fourth (December) quarter of 2024.”

Additionally, at Warrior Met Coal’s Mine 7 East, RMI is undertaking an overhaul and upgrade program for the mine’s aging S500 units, which have been in service since 2011. “We will be installing new S500 pumps on the pump systems serving the mine’s longwall equipment,” Punton remarked, underscoring the longevity and reliability of the equipment which is highly regarded in the mining industry.

In the industrial domain, RMI recently secured a contract to provide an S500 pump assembly for a press system at Arconic’s Lafayette facility in Louisiana. “We assembled and tested this S500 pump system in our Jasper facility in Alabama, and shipped it to the customer early this year for commissioning during the third quarter of the year,” Punton added.

The Quinmax S500 pump, featuring 650 hp (485 kW) motors, is noted for its compact horizontal five-plunger design, which enhances crank speeds and loading. This design ensures a safe and reliable supply of high-pressure water-based fluids for both mining and heavy industrial applications. RMI employs finite element analysis to validate the performance and reliability of its pumps and computational fluid dynamics to optimize the efficiency of wetted components.

By Daniel Gleeson