Article Summary

Growing measures to minimize the hazardous impacts arising from wastewater streams have forced the advancement of various wastewater, sludge treatment and dewatering systems. This article examines the global dewatering equipment market share and discusses the benefits of several technologies utilized for dewatering various waste sludges. The sludge dewatering effectiveness of belt filter press and decanter centrifuge technology is compared at a US Gulf Coast refinery.

More economical solutions

The current world economic environment has forced refiners to process various alternative feedstocks in order to generate higher margins. Processing opportunity crudes comes at a cost of removal of higher levels of pollutants and generation of proportionately larger amounts of sludge as a treatment byproduct in waste treatment facilities. Consequently, more economical solutions to sludge processing and disposal are sought after by these industries. The global sludge dewatering equipment market was valued at $4545 million in 2019 and is projected to reach $5356 million by 2025 at a compound annual growth rate (CAGR) of 4.4%. The market value of sludge dewatering equipment in the United States is projected to expand at 9% CAGR by 2025, driven by declining available water resources along with ageing wastewater treatment infrastructure. Rising focus toward protection of surface waters from the adverse effects of wastewater discharges along with rapid technological advancements as a part of the circular economy will drive this market. Globally, North America and Europe continue to dominate sludge dewatering equipment utilization, accounting for approximately 60% of the total market share.

Municipal sludge processing accounts for about one-third of the total market share, with industrial sludge processing ranked second highest

Sludge dewatering is an integral part of any sludge processing and disposal scheme. Removal of water from the sludge yields a product which is relatively safe to handle and drastically reduces the disposal quantities of sludge. Sludge dewatering operations have made tremendous progress since the commissioning of the first wastewater treatment plant in Massachusetts in the late 19th century and considerable innovation has been applied to what has long been regarded as a high-cost operation. Additionally, vast amounts of research have been conducted to identify critical factors that affect dewatering operations, allowing for process improvements regardless of the dewatering technology being utilized. Dewatering equipment manufacturers have leveraged this research to offer machinery that dewaters sludge more thoroughly and efficiently. However, there is no ‘one size fits all’ technology, but rather choosing the right equipment is based upon waste stream, size of facility, budget, staff, and other factors.

Sludge dewatering provides a concentrated and consolidated product, sludge cake, which retains most of the solids from the original sludge along with a diluted stream that is predominantly water. The diluted stream is usually directed back to the inlet of the wastewater treatment system. Depending on the sludge type and equipment utilized for dewatering, the concentration of dry solids in sludge cake generally ranges between 10% and 45%. Sludge cake is not a free-flowing product and instead forms aggregate lumps which can be easily transported through a conveyor belt or a screw-type conveyor into roll-off boxes for disposal.

The most common dewatering technologies utilized to dewater wastewater sludge are:

- Belt filter press, filter press, screw press: pressing the sludge against a permeable medium

- Centrifuge: rotating the sludge in a cylindrical vessel to force the denser solids to the internal walls of the vessel and the water to its center

- Rotary press: forcing the sludge through a narrow, parallel flow channel with porous walls

- Sludge drying bed: allowing the liquid to drain under gravity through a permeable medium and evaporate under ambient conditions

Sludge dewatering technology overview

Globally, centrifuge dewatering accounts for a 25% of the market share while belt filter presses and screw presses only account for 9% of the technology utilized for sludge dewatering. Belt filter presses however are one of the most common sludge dewatering technologies used in the North America.

In a typical dewatering operation, sludge disposal in municipal and industrial wastewater treatment plants represents the bulk of the cost of operations. These costs can account for up to 60% of the total dewatering costs, and will depend on the size of the plant and wastewater sludge. With the correct sludge technology in place and an efficient sludge dewatering operation, wastewater treatment operators can easily realize significant savings in disposal costs.

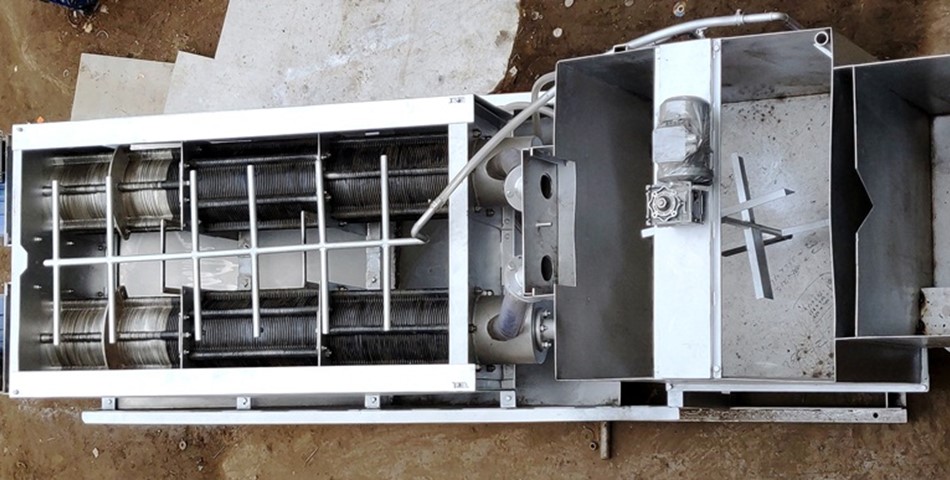

Belt filter press

When dewatering sludge using a belt filter press, the chemically conditioned sludge is first conveyed along a porous gravity drainage section where approximately 50% of the water is removed. The sludge is then subjected to pressure as it passes between two recirculating belts forming a wedge zone at the inlet, which travels over rollers. The squeezing action of the two belts exerts both shearing and compressive forces on the sludge in the pressure zone, causing it to release more water. The overall process produces a dewatered product, commonly known as sludge cake, which has a dry solids content of between 10% and 35%. Belt presses offer high dewatering capacity and relatively high dewatering efficiency. Belt press operation is easily managed and has low energy consumption.

The major drawback to using a belt filter press is that it does require more operator attention, daily maintenance, and greater wash water usage compared to other technologies. This is especially true when processing a highly variable sludge feed as low influent stream solids increase water in the sludge cake. If left unattended, variation in solids concentration or sludge composition (presence of oil or grease) will cause belt filter blinding and lower the solids content in the sludge cake. Belt washing at the end of each shift or upon shutdown is also a must as residual solids will cause pore plugging those compromises dewatering operation.

Centrifuge

Centrifuge dewatering utilizes centrifugal forces to remove excess water from the sludge slurry. The most common type of centrifuge used for dewatering applications is the solids bowl centrifuge (referred to as a decanter). The sludge slurry is introduced into the feed chamber assembly, which is accelerated up to speed in the feed chamber and discharged into the pond of the bowl through the feed ports. The g-force generated through bowl rotation causes the solids to separate and build up against the bowl wall. These solids are then pushed to the opposite end of the liquid discharge by the screw conveyor, which rotates at a slightly different speed to that of the bowl. Solids travel up an incline and ultimately out of the equipment while centrifugal force is constantly exerted in order to produce the desired solids concentration in the product. The g-force, pond settling, differential speed and flow rate influence the clarity of the liquid and solids concentration in the product. In general, centrifuges produce a drier product and have a higher throughput capacity with a smaller footprint. Also, highly variable concentrations of feed sludge solids do not negatively impact the dewatering process. The major drawbacks, however, are high capital investment, power usage, and maintenances costs. A detailed comparison between centrifuge and belt filter press processes.

STAN BARSKOV and CODY HARPER

www.digitalrefining.com/