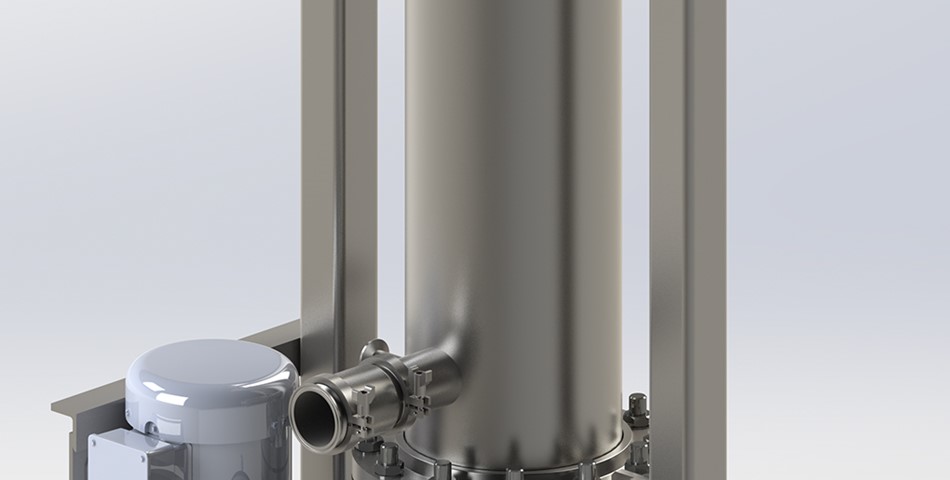

Spiral Water Technologies, a developer of advanced filtration solutions for difficult-to-treat waters, introduces the Model S1000 automatic self-cleaning filter. Made with a robust stainless steel housing, the new Model S1000 can be used for both process and wastewater streams.

Designed to remove ultra-high and variable total suspended solids (TSS) from difficult-to-treat fluids in industrial process and wastewater treatment applications, it is ideal for use in such markets as food and beverage, power, chemicals, metals, and mining.

"Given the strong market pull for our technology in the industrial and wastewater markets, we have invested in a robust stainless steel filter for high flow, high temperature and high pressure applications," said Ashwin Gulati, President and CEO of Spiral Water. "We look forward to working with our customers and partners to provide an innovative and cost effective way to solve their filtration and product recovery needs."

With a maximum flow rate of 1360 cubic meters per day (250 gpm), the S1000 is designed for over three times the flow of Spiral Water's Model 800 Series, the company's initial product. It can also operate at higher pressures up to 10.3 bar (150 psi) at 70 F, and at higher temperatures up to 105 C (220 F).

Multiple filters can be set up in parallel for higher flows. Spiral Water's filtration technology differs from traditional automatic self-cleaning technologies in multiple ways. Not only do the energy efficient units provide solids concentration; they are capable of finer filtration and can filter up to 250 times dirtier water than traditional automatic self-cleaning filters while achieving up to 99 percent water recovery.