When Brookberries took over a tomato greenhouse for strawberry cultivation, they encountered ozone disinfection for treating drain water. The strawberry growers from Limburg have significantly expanded in recent years.

In anticipation of new construction projects, ozone disinfection emerged as the sole option. Growers embraced it and honed their understanding of its optimal use. This became evident during our visit to the water room of the newest location in Belfeld at the end of February.

Situated at Elshoutweg 28 in Belfeld, Brookberries' newest greenhouses cover a total of 30 hectares across 5 locations. Walking alongside the concrete path next to the greenhouse, grower Luuk van den Eertwegh led us towards the water technical room.

The spacious water room has room earmarked for future expansion, allowing for an additional 4 hectares to be added to the current 9.6 hectares, necessitating expansion of current installations.

In the company hall, a row of silos with a smaller black tank in front caught our attention. This belonged to the Hortizone, the ozone installation in which the growers have reinvested. Their aim is to achieve disease-free and oxygen-rich irrigation water through ozone treatment, effectively addressing two concerns simultaneously.

In Belfeld, spring water, rich in iron, is utilized. Rainwater, avoided for irrigation due to tannic acid produced by decomposing oak leaves, is only used to cool the greenhouse roof in August.

Noud Dings, son of owner Marcel, and Luuk, cousin of owner Peter, represent the new generation of growers. They've experienced various water systems across the company's locations and understand the risks posed by diseases like red root rot and Phytophthora in strawberries.

Clean irrigation water is paramount for the growers. With the Hortizone, they ensure adequate oxygen levels in the irrigation water, significantly reducing the risk of diseases. Werner van Mullekom, account manager of greenhouse horticulture at Agrozone, highlighted that the Hortizone can increase oxygen content by up to 300 percent.

The Hortizone treats water batch by batch, taking approximately 18 minutes to treat 1 batch of 4 cubic meters. Peter van den Eertwegh recalls their initial encounter with ozone technology in a former tomato greenhouse in Tegelen, where they had to explore alternatives due to a failing water disinfection heater.

Optimal operation of the Hortizone requires customized settings, particularly regarding water acidity. Collaboration between growers, Agrozone, and installer Cogas has led to fine-tuning of these settings for each situation.

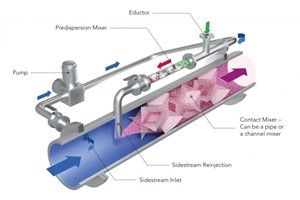

An automatic sensor cleaner at the Hortizone ensures the redox sensor remains clean, crucial for maintaining disease-free water. For future expansion, Brookberries has the option of an inline model of the ozone unit, the Aqualine, capable of treating up to 150 cubic meters of water per hour.

Peter emphasizes their commitment to continuous improvement, stating, "As long as the water enters the ozone installation with the right quality, it comes out clean and oxygen-rich."