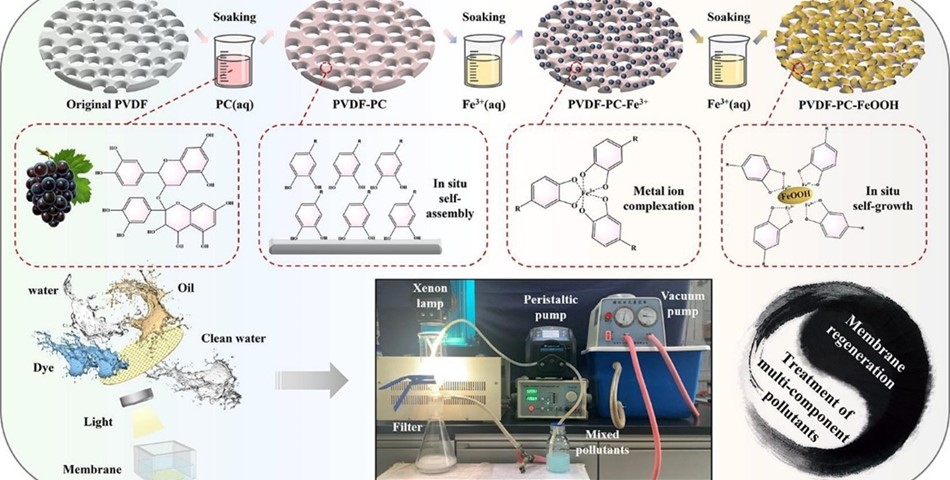

This study addresses the simultaneous removal of insoluble oils and soluble organic dyes from wastewater using a novel PVDF-PC-FeOOH membrane. Hydroxyl iron oxide growth on PVDF membranes is achieved through in situ self-assembly and in situ self-growth, facilitated by proanthocyanidins.

The resulting membrane exhibits exceptional wettability and photo-Fenton catalytic properties. It demonstrates underwater oil contact angles exceeding 150° and degrades methylene blue with over 70% efficiency within 20 minutes. The membrane achieves an impressive emulsion separation flux of 976.1 L·m-2h−1 with 99.7% efficiency.

The photo-Fenton catalytic degradation process is discussed, highlighting a regeneration rate exceeding 90% and a steady flux of 158.7 L·m-2h−1 over a continuous 60-minute filtration process. The innovative approach allows simultaneous removal of mixed pollutants and membrane regeneration in a single step.

In the context of multi-component oily wastewater, the membrane selectively adsorbs cationic dyes, achieving a remarkable removal rate of 98.6%. This strategic framework enhances the practical application of membranes in filtering oily wastewater and proves valuable in the selective separation of dyes within the dyeing and printing industry.

The article discusses the increasing challenge of treating oily wastewater discharged by industries, particularly focusing on the printing and dyeing sector, which contains non-biodegradable organic dyes harmful to the environment. The conventional membrane separation technology faces difficulties in simultaneously removing oils and dyes due to molecular differences and fouling risks. To address this, the study introduces a novel PVDF-PC-FeOOH membrane, combining proanthocyanidins (PC) and hydroxyl iron oxide (FeOOH) for effective and simultaneous removal of oils and dyes.

Previous studies have employed various materials like silk fibroin (SF), dopamine hydrochloride (DA), and carbon nanotubes (CNTs) for membrane preparation. However, these membranes often require chemical regeneration, causing secondary pollution. The PVDF-PC-FeOOH membrane stands out for its multifunctionality, incorporating superhydrophilic/underwater superoleophobic properties and photo-Fenton catalysis. The article highlights that this membrane can efficiently treat multi-component oily wastewater in a single step while facilitating in-situ regeneration during the photo-Fenton process.

The use of proanthocyanidins (PC) in the membrane enhances hydrophilicity through covalent and non-covalent interactions. Additionally, hydroxyl iron oxide (FeOOH) serves as a stable photo-Fenton catalyst with excellent adsorption properties. The membrane's ability to selectively adsorb cationic dyes makes it practical for the filtration of oily wastewater in the printing and dyeing industry. The study emphasizes the potential of the PVDF-PC-FeOOH membrane for its eco-friendly and efficient approach to addressing the challenges associated with industrial oily wastewater treatment.

Conclusion

In brief, our method yields a PVDF-PC-FeOOH membrane with outstanding wettability. This membrane exhibits remarkable emulsion separation flux and efficiency, reaching 976.1 L·m-2h−1 and 99.7%, respectively. Through a continuous adsorption-regeneration-re-adsorption cycle, the membrane achieves a regeneration rate exceeding 90%. Notably, when coupled with the photo-Fenton catalytic process, our approach enables the simultaneous removal of mixed pollutants and membrane regeneration in a single, efficient step.

By Huasheng Yang, Yanzong Zhang, Chengyi Huang, Lilin Wang, Lulu Long, Jinsong He, Chao Chen, Gang Yang, Yan Liu

https://www.sciencedirect.com/

Edited by Yehya Aoun