Increased levels of chlorate in different foodstuffs and drinks are forcing industry to rethink its products. Chlorates are salts of chloric acid, which can be harmful to our health. High absorption of chlorate can destroy membranes of red blood cells.

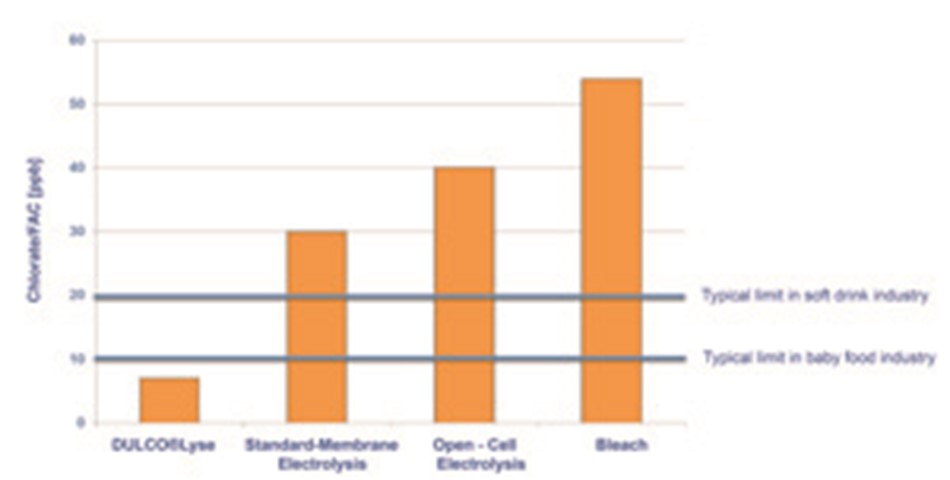

An increasingly popular disinfectant in the food and beverage industry, electrochemically activated (ECA) water, contains this unwanted salt. Standard disinfection processes produce chlorate concentrations far above the desired minimum limits.

Is there a system that delivers optimum water disinfection for food and beverage production, yet is economical, eco-friendly and does not contain harmful concentrations of chlorate or chloride?

Apart from the concentrations of chlorate already found in food, like vegetables, fruit or milk products, this harmful salt is produced as a by-product when using disinfectants containing chlorate. The concentration of chlorate caused by disinfection in the production and processing process therefore has to be reduced to a minimum.

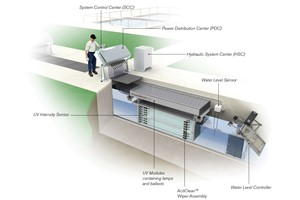

ProMinent, which has specialized in water disinfection, has optimized its diaphragm electrolysis process Dulcolyse to meet the aforementioned objective. This unique and efficient process guarantees a chlorate content, significantly below the required limit values, and a very low chloride content.

It offers effective, long-term and eco-friendly disinfection of process water and production equipment while preventing the formation of biofilms. The on-site system uses just water, sodium chloride and electricity to produce the inexpensive disinfectant Dulcolyt 400.

Minimal chlorate content with maximum effectiveness

With ready-to-use disinfectants, the chlorate content can more than double depending on the ambient temperature and storage period. By contrast, the amount of Dulcolyt 400 required is produced on site and metered directly into the process.

The disinfectant is thus not exposed to temperature fluctuations and is not affected by long periods of storage. Moreover, unlike other disinfectants produced by electrolysis, the chlorate concentrations of this smart disinfectant are many times lower.

Less than 0.01 ppm (10 ppb) of chlorate is produced when metering 1 ppm of FAC (Free Available Chlorine). Other advantage: the extremely low chloride content of this disinfectant. It is significantly below the level of comparable processes, which often contain more than many times as much chloride. This almost completely eliminates harmful corrosion in machinery and pipework, providing an invaluable benefit.

Disinfection with added value

The described innovative diaphragm electrolysis process is an efficient and cost-effective alternative to conventional disinfection processes. It delivers reliable, safe disinfection for food and beverage manufacturing without the need to transport, handle or store highly concentrated and hazardous chemicals.

The special disinfection process reliably minimizes the concentration of chlorate throughout the food and beverage production chain, at the same time as ensuring excellent process reliability, thanks to very accurate metering. The safe disinfection effect has been proven to have an optimum and reliable bactericidal, viricidal and fungicidal efficacy.

Other advantages include low impact on people, machinery and products, less cost for preservatives and chemicals, and high efficiency thanks to reduced water consumption and time savings. This also has been confirmed many times over in countless independent lab tests and in successful industrial use with major producers of soft drinks, dairy products and baby food.